Steps towards home manufacturing with robotics and 3D printing

/Value yourself: offload manufacturing to 3D printing + robotics to concentrate on what matters

A 3D printer’s number one operating cost is time. Material is trivial compared to the time it takes someone to setup and service the printer and the time it takes to print your part. Moreover, the majority of desktop 3D printers' times is spent NOT printing anything. They are mostly idle. Most people don't run their printer 24/7. We want the limiting factor to be the human’s creativity and not the tool’s limitations, and right now the 3D printer requires too much human attention to be worth it.

Imagine setting up a 12 hour long print to run overnight, only to come back the next day and find it warped so much it’s lifted the blue tape from the platform. Unable to counter the physics of contracting plastics as they cool, you decide to split the model into smaller parts which offers you both faster print times per part (useful if errors occur) and less warping. However, now every several hours you have to come back to remove the print and start a new print. Not convenient at all. Well, no more! It’s the future now, and we have robots to help us.

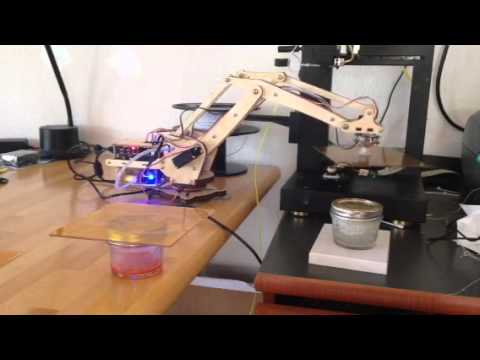

The original idea was a desktop robotic arm that could load and unload a queue of jobs for the 3D printer. Lost time at night or while busy with something else could be recuperated -- the limiting factor would now become the human designer queuing enough jobs!

Check out how far Cuddleburrito has come to attain this vision:

The core responsibility of the system is loading and unloading the glass platforms from the printer. I started sketching out ideas months before finding this Kickstarter project, but I am so glad to have been able to be a backer. The servo power arm is much better than what I could have built. The arm is Arduino powered and comes with an active suction cup too. The video was the first test ( after furiously assembling it ) of moving glass platforms on and off the 3D printer.

The dream of home desktop manufacturing suddenly seemed feasible at this point, but I quickly realized how much more there was to do.

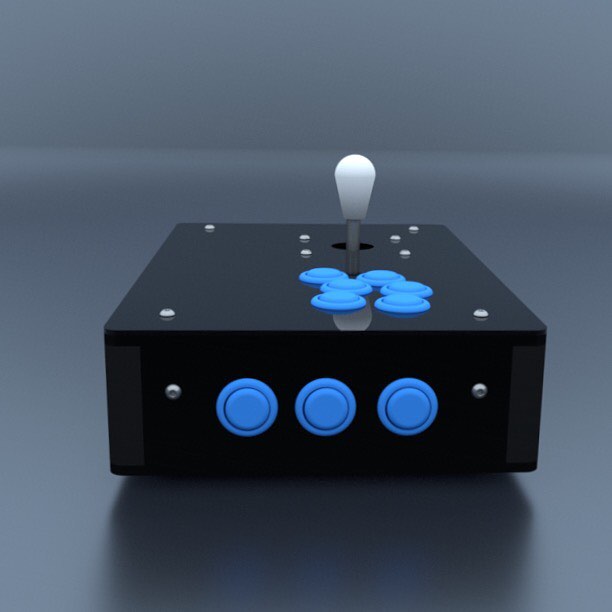

My printer shipped with binder clips to clamp the glass platform to the heating bed. These binder clips need to be removed to swap out the glass platforms, but they each require a lot of force and dexterity. I started with long levers but had problems with the binder clip flying out; the triangular shape is naturally unstable! I like to keep things simple but it was clear I had to build a new clamping system.

The solution I've reached for now are magnetic clamps the arm drops into place. Here’s the magnetic clamp being removed and reattached. You can hear the magnets 'clicking' the part into place:

The next step is obviously printing a matching mechanism for the other side and ensuring there is in fact enough clamping force. However, I'll be out of town for the next week so it'll have to wait.

Robotics + 3D printing opens up new possibilities for expression and digital creation. A chess set could be finished much faster if it ran 24/7 autonomously. Small scale manufacturing for proof of concept and prototyping would become accessible to more entrepreneurs and makers.

Cuddleburrito believes that we’re entering an age of local digital manufacturing, where your local town’s network of 3D printers can make a steady supply of parts so that local individuals can make what they need. All the while, this ecosystem would be integrated into and directly support local economies. Let's cuddleburrito. Let's work together to build something greater.